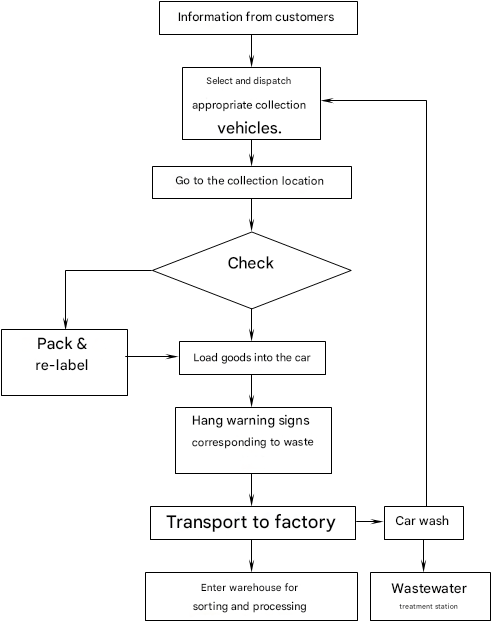

Waste Collection and Transportation

The waste collection and transportation process will be carried out according to the process diagram in the...

-

Based on customer information regarding the type and quantity of goods to be collected, suitable types of vehicles and their load capacities will be dispatched to the collection site. Typically:

- For liquid waste: a tank with a capacity of 12 m3 will be used for collection.

- For other types of waste: 0.5-ton, 1-ton, 2-ton, and 5-ton trucks with enclosed stainless steel frames will be used.

-

All transport vehicles are equipped with emergency response equipment as per legal regulations to address any incidents that may occur during transportation.

-

Production plants will assign their staff to package Hazardous Waste (CTNH) before the transport vehicle arrives. Upon arrival at the collection site, technicians from Thanh Tung 2 Co., Ltd. will inspect the packaging condition, container integrity, waste composition, and quantity. If the containers are made of materials compatible with the waste inside (non-reactive to the waste) and meet technical requirements (such as leak resistance, impact resistance, etc.) and provide sufficient information and warning signs, the waste will be allowed to be loaded onto the vehicle. In case the waste is not properly packaged or lacks information, it will be repackaged before loading onto the vehicle.

-

After loading the goods onto the vehicle, warning signs corresponding to the type of waste being transported will be attached to both sides and the rear of the vehicle according to the regulations for transporting Hazardous Waste.

-

After completing the above steps, the waste will be transported to the plant. Upon arrival, technicians will recheck the condition and weight of the waste, as well as follow the prescribed procedures for Hazardous Waste inventory management. The waste collection vehicle will be cleaned before the next collection round, and the wash water will be treated in the wastewater treatment system to meet the specified standards.

-

The waste collection at the source is carried out by the workers at Thanh Tung 2 plant. The collection time depends on the agreement between the company and the waste source owner, aiming not to hinder the company's production and minimize incidents for humans and the environment. The collection cycle depends on the type of waste from the waste source.

Receipt and Classification of Waste

Transport vehicles bringing waste to the plant will deposit the waste in the appropriate storage areas according to guidelines. If any issues arise, the responsible transport personnel must notify management for timely adjustments.

After unloading and arranging the waste, the responsible transport personnel carry out necessary paperwork, such as signing confirmation in the transport log and handing over the Hazardous Waste Certificate to management. Management verifies and signs confirmation of the completed waste transportation.

Waste is classified and stored as follows:

- Non-hazardous industrial waste is placed in the industrial waste storage area, then manually sorted and stored separately.

- Hazardous industrial waste is classified based on solid/liquid/sludge states and waste in drum containers. It is then taken to three separate areas within the Hazardous Waste Storage: solid waste storage area, liquid waste storage area (sludge is also stored here), and drum storage area.

- Recycled products are grouped in the finished product warehouse, which is further divided into different areas: drum storage area, lubricant storage area, solvent storage area, lead storage area, and plastic storage area.

- Hazardous warning signs are posted in all storage areas for Hazardous Waste.

Recycling and Waste Treatment

Stored waste is sent to corresponding treatment systems:

- Used lubricant recycling system: Processes contaminated lubricants.

- Solvent recycling system: Processes various types of waste solvents.

- Plastic recycling system: Processes plastic scrap, packaging, and nylon.

- Drum cleaning and recycling system: Cleans dirty Hazardous Waste drums, restores and repaints them.

- Electronic waste recycling system: Processes electronic components and waste.

- Battery dismantling system: Dismantles batteries, processes waste solvents.

- Lead recycling system: Recycles lead waste, lead slag.

- Fluorescent lamp treatment system: Processes old, damaged, or broken fluorescent lamps.

- Hazardous waste treatment system (inorganic, organic): Treats inorganic liquid waste and organic liquid waste.

- Incineration system: Treats waste with incineration capabilities, including waste collected from waste sources and waste generated from plant operations.

- Solid stabilization system: Stabilizes, solidifies ash, slag, and hazardous components.

- Waste disposal area: Landfills non-hazardous industrial waste and Hazardous Waste.