Waste Incineration

The project involves the investment in three waste incinerators. Specifically: Phase 1 includes the investment in one IV-203-300 incinerator with a capacity of 300 kg/hour. This incinerator is manufactured in Japan and the technology was transferred to THANH TUNG 2 factory, making it the first incinerator technology of its kind in Vietnam.

Phase 2: An additional IV-203-300 incinerator with a capacity of 300 kg/hour and one rotary kiln incinerator model LQ-1000 with a capacity of 1 ton/hour are invested.

IV-203-300 Incinerator, Capacity 300 kg/h

-

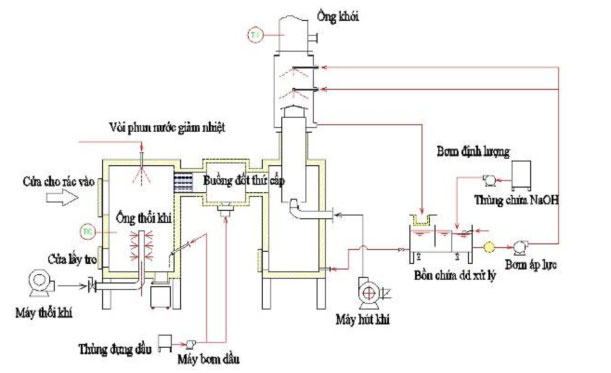

Technological Process

The technological process of the IV-203-300 waste incinerator is presented below.

Operating Principle Diagram of the IV-203-300 Incinerator

-

Technology Scale and Technical Specifications

a) Fuel Characteristics

The fuel used in the project consists of industrial solid waste (ISW) and hazardous waste (HW), including:

-

Mixed industrial solid waste

-

Solid waste from wood processing, rubber, and paper industries

-

Oil-contaminated solid waste, paint sludge, and chemical packaging

The list of waste types that can be incinerated is presented in Table 1.13.

Table 1.13: List of Waste Types Suitable for Incineration in the IV-203-300 Incinerator

| No. |

Waste Type |

State |

HW Code |

| 1 |

Tar and waste coal |

Solid |

01 04 06 / 11 03 02 |

| 2 |

Solid waste containing paint or varnish with organic solvents or other hazardous components |

Solid |

08 01 02 |

| 3 |

Solid waste containing oil from maintenance activities of facilities, machinery, equipment |

Solid |

01 04 05 / 01 04 07 |

| 4 |

Solid waste containing hazardous Silicon |

Solid |

02 08 01 |

| 5 |

Solvents from wastes containing solvents, varnish |

Solid |

07 01 06 |

| 6 |

Ink and waste from printing |

Solid |

08 02 04 |

| 7 |

Solid waste from wood processing, paper and pulp industry containing hazardous components |

Solid |

09 01 01 |

| 8 |

Leather waste containing hazardous substances from tanning processes |

Solid |

10 01 02 |

| 9 |

Combustible solid waste containing hazardous components |

Solid |

03 04 09 / 06 01 07 / 12 02 05 / 12 03 02 / 12 04 02 / 12 09 01 / 17 05 01 |

| 10 |

Solid waste containing infectious agents |

Solid |

13 01 01 |

| 11 |

Waste containing residual pesticides |

Solid/sludge |

14 01 01 |

| 12 |

Waste containing residual herbicides |

Solid/sludge |

14 01 02 |

| 13 |

Expired or unused plant protection chemicals |

Solid |

14 01 04 |

Source: Investment Project, 2012.

Rotary Kiln Incinerator LQ-1000

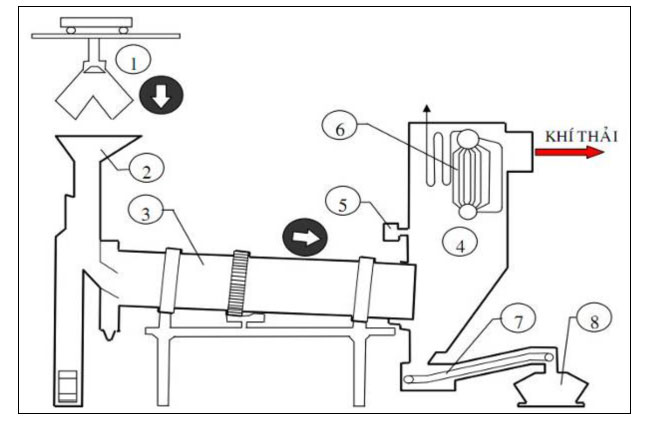

Operating Principle of the LQ-1000 Incinerator

The basic principle of a rotary kiln incinerator system includes the following components: waste feeding unit, primary chamber (rotary kiln) with a volume of 9.5 m³, secondary chamber (static furnace) with a volume of 4.75 m³, and an ash removal system.

-

The rotary kiln incinerator's primary chamber is a rotating drum with adjustable speed, responsible for mixing the solid waste during combustion. The incinerator is installed at a slope of approximately 1/100 to allow automatic movement of the waste from the feeding point to ash discharge. The drying, vaporization (pyrolysis), carbon combustion, and ash removal processes occur in this rotary drum sequentially from the waste being fed into the combustion chamber until it turns to ash.

-

The secondary combustion chamber is a static chamber designed to burn the volatile substances and gases generated from the pyrolysis process in the primary chamber. The operating temperature ranges from 950°C to 1300°C. The gas retention time in the secondary chamber is maintained at 2 seconds to comply with QCVN 30:2010/BTNMT standards. The minimum excess oxygen required for combustion is 6%. The secondary chamber is often integrated with an energy recovery system such as a boiler (for generating high-pressure steam to drive turbines or produce hot water, etc.).

Diagram of the LQ-1000 Rotary Kiln Incinerator

Trong đó:

| Symbol |

Description (Vietnamese) |

Symbol |

Description (English) |

| ① |

Cầu trục nâng rác |

… |

Primary burner nozzle |

| , |

Phễu nhận rác |

† |

Boiler |

| ƒ |

Buồng đốt thùng quay |

‡ |

Ash conveyor |

| „ |

Buồng đốt thứ cấp |

^ |

Ash bin |

1) Technology Process

The technological process of the rotary kiln incinerator is illustrated in .S

Rotary Kiln Technology Diagram

-

Technology Scale and Technical Specifications

a) Technical Specifications

The technical specifications of the LQ-1000 kiln are shown in

Technical Specifications of the LQ-1000 Kiln.